How to Manage Empty Shipping Containers Effectively and Save Costs

The management of empty shipping containers is a critical logistical challenge that has garnered significant attention in recent years. According to the International Maritime Organization, there were approximately 24 million TEUs (Twenty-foot Equivalent Units) of empty containers in circulation globally in 2022, a figure that highlights the pressing need for efficient management strategies. Ineffective handling and storage of these empty shipping containers not only contribute to increased operational costs but also put considerable pressure on supply chain efficiency. In fact, the Global Logistics Report estimates that poor empty container management can lead to shipping costs escalating by 10-20%, adversely impacting profitability.

Implementing effective strategies for managing empty shipping containers can result in significant savings and operational improvements for logistics companies. Research from industry analysts at McKinsey & Company indicates that optimizing the turnaround and repositioning of empty containers can minimize idle time and maximize asset utilization, thereby enhancing overall supply chain performance. By employing advanced tracking technologies and adopting a proactive approach to inventory management, companies can harness data-driven insights, ultimately allowing for smarter fleet management decisions. This not only leads to cost reduction but also supports a more sustainable logistics framework by reducing the carbon footprint associated with unnecessary transport and emissions generated by idling containers.

Understand the Importance of Managing Empty Shipping Containers

Effectively managing empty shipping containers is crucial for businesses that rely on logistics and supply chain efficiency. Empty containers take up valuable space at ports and warehouses, leading to increased costs related to storage and handling. By understanding the importance of managing these containers, businesses can streamline operations, minimize unnecessary expenditure, and enhance overall productivity.

One of the key aspects of effective management is the implementation of a robust tracking system. This allows companies to monitor the location and status of their empty containers in real time, ensuring they are not stranded at ports or depots longer than necessary. Regular audits can help identify under-utilized or idle containers, enabling businesses to optimize their fleet and reduce holding costs. Additionally, developing strategic partnerships with container depots and transport providers can facilitate quicker turnover of empty containers, contributing to better operational flow.

Furthermore, companies should consider innovative reuse and recycling options for their empty containers. Instead of viewing these containers solely as temporary assets, organizations can explore alternative uses, such as converting them into storage solutions or even mobile offices. This not only maximizes the value of each container but also reduces the need for additional investments in new infrastructure. By adopting a comprehensive approach to managing empty shipping containers, businesses can achieve significant cost savings and foster a more sustainable logistical framework.

Assess Your Current Empty Container Management Practices

Assessing your current empty container management practices is crucial for optimizing operations and reducing costs. Begin by conducting a thorough audit of your existing processes, including how containers are tracked, where they are stored, and the frequency of their movements. This evaluation should involve key stakeholders in your logistics and supply chain teams, as their insights can provide valuable information about inefficiencies and potential improvements.

Next, analyze the data collected during the audit to identify patterns and irregularities in container usage. Consider implementing a digital tracking system that allows real-time visibility of container locations and statuses. By utilizing technology, you can facilitate better decision-making and improve communication between teams. Additionally, explore strategies such as optimizing container sizes for particular shipments or reducing the number of empty moves by aligning inbound and outbound shipments. Adopting these practices can lead to substantial savings and a more streamlined supply chain.

How to Manage Empty Shipping Containers Effectively and Save Costs - Assess Your Current Empty Container Management Practices

| Container Type | Total Containers | Empty Containers | Days in Port | Cost per Day ($) | Total Cost ($) |

|---|---|---|---|---|---|

| 20 ft Standard | 150 | 40 | 10 | 5 | 200 |

| 40 ft Standard | 200 | 60 | 15 | 7 | 420 |

| 40 ft High Cube | 100 | 30 | 8 | 6 | 144 |

| Reefer | 80 | 20 | 12 | 9 | 180 |

| Flat Rack | 50 | 10 | 20 | 4 | 80 |

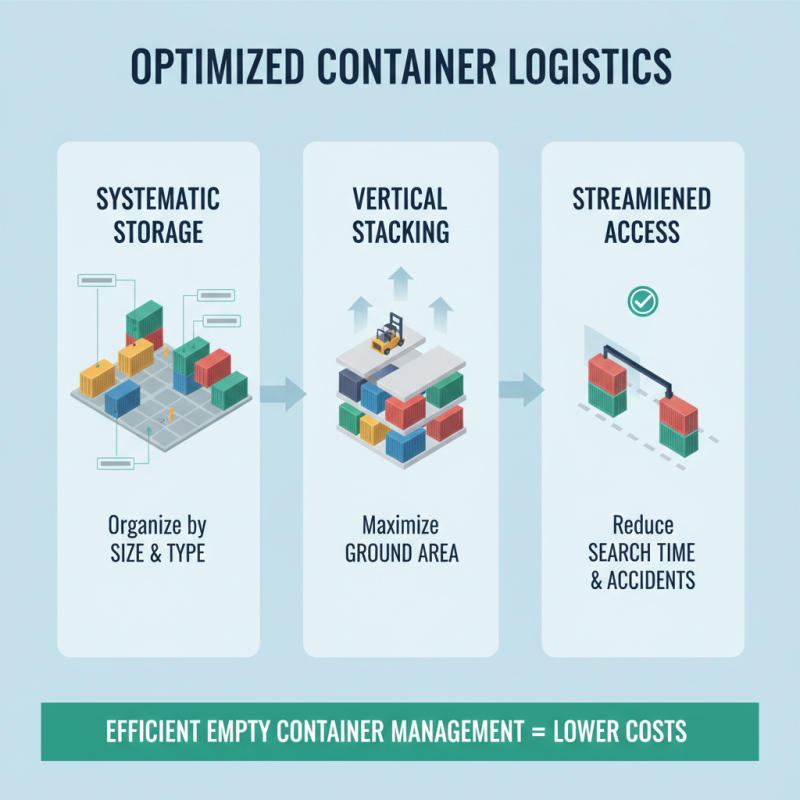

Implement Strategies for Efficient Container Storage and Handling

Efficient management of empty shipping containers is crucial for businesses looking to optimize logistics and reduce operational costs. One effective strategy is to implement a systematic storage solution. By organizing containers in designated areas based on size and type, companies can streamline access and reduce the time spent searching for specific units. Additionally, using vertical space to stack containers adequately can free up valuable ground area and allow for easier maneuverability, thereby minimizing the chances of accidents or damages.

Another key element in managing empty containers is adopting technology for tracking and monitoring. Utilizing an inventory management system can provide real-time data on container availability and location. This information helps in planning and forecasting container usage, ensuring that excess containers are not accumulated unnecessarily. Regular audits and assessments of container usage patterns also facilitate timely decision-making regarding which containers to keep or dispose of, further supporting cost-saving initiatives. By focusing on these strategies, businesses can enhance their operational efficiency while effectively managing empty shipping containers.

Explore Cost-Effective Solutions for Container Transportation

Effectively managing empty shipping containers is crucial in today’s competitive logistics landscape, especially when striving for cost-efficient transportation solutions. A recent report from the International Transport Forum (ITF) suggests that empty container repositioning costs account for approximately 20% of the total shipping expenses in the industry. By implementing strategic planning and real-time data analytics, companies can optimize their container utilization, minimizing unnecessary movements and reducing operational costs.

One effective approach involves leveraging technology for container management. Internet of Things (IoT) devices can provide real-time tracking of container locations, enabling logistics managers to make informed decisions regarding reallocation. According to a study by McKinsey, integrating advanced data analytics into supply chain processes can reduce transportation costs by up to 15%. Additionally, collaborative logistics networks can be established, allowing companies to share empty containers with other shippers when not in use, thus maximizing asset utilization. Such practices not only help in cutting down costs associated with empty containers but also contribute to a more sustainable shipping environment.

Evaluate Technology and Tools for Tracking Empty Containers

Tracking empty shipping containers effectively is crucial for companies aiming to save costs and optimize their logistics operations. Technology plays a vital role in this process, offering various tools that enhance visibility and management of containers. Utilizing GPS tracking systems can provide real-time data on container locations, allowing businesses to monitor their assets and reduce the risk of loss or misplacement.

Tips: Implement RFID technology alongside GPS to enhance tracking capabilities. RFID tags attached to containers can provide immediate access to detailed information about the container’s status, ensuring that you always know its condition and availability. This dual approach not only improves tracking efficiency but also streamlines the logistics workflow.

Additionally, employing container management software can revolutionize how empty containers are monitored. Such platforms consolidate data regarding the location and status of multiple containers, making it easier to identify potential bottlenecks or inefficiencies in the supply chain. By analyzing trends in container usage, businesses can make informed decisions about when to reposition containers, ultimately leading to reduced shipping costs.

Tips: Regularly review your tracking and management systems’ performance to identify areas for improvement. Leveraging data analytics can help optimize container usage, reduce idle time, and cut down shipping expenses significantly.