Top Benefits of Using Refrigerated Containers in 2025 for Food Transport

In 2025, the food transport industry stands at a pivotal juncture, where the adoption of refrigerated containers has emerged as a critical solution for ensuring food safety and minimizing waste. With the global market for refrigerated containers projected to grow at a CAGR of approximately 10% from 2021 to 2026, industry professionals recognize the pivotal role these units play in maintaining the integrity of perishable goods during transit. As noted by industry expert Dr. John Miller, "Refrigerated containers are not just an asset; they are a necessity for the future of food logistics," highlighting an increasing reliance on temperature-controlled shipments.

The advancements in refrigerated container technology have significantly enhanced their efficiency and effectiveness, allowing for consistent temperature management, energy conservation, and even remote monitoring capabilities. According to the World Food Programme, nearly one-third of food produced globally is wasted due to inadequate infrastructure and transportation methods. By utilizing refrigerated containers, stakeholders can cut down on spoilage rates, thereby improving food security and reducing economic losses. With environmental concerns also coming to the forefront, the move toward more sustainable refrigeration practices in these containers represents a step forward in addressing climate change impacts on food transport.

In summary, 2025 is set to witness transformative changes in food transport facilitated by refrigerated containers, paving the way for enhanced safety standards, sustainability, and economic efficiency. As the industry evolves, the synergy between innovative technology and logistics practices will become increasingly crucial in overcoming the challenges of food transportation in the modern era.

Key Advantages of Refrigerated Containers for Food Transport

Refrigerated containers have become indispensable in the food transport industry, particularly as global demand for fresh and perishable goods continues to rise. According to a recent report by the International Institute of Refrigeration, the global cold chain market is projected to grow to $626 billion by 2025, highlighting the crucial role of efficient temperature-controlled transport systems. These refrigerated containers not only ensure that food products maintain their quality during transit but also significantly reduce waste and spoilage rates. Research indicates that an estimated 1.3 billion tons of food are wasted globally each year, and effective refrigeration solutions can mitigate a substantial portion of this loss.

Moreover, the advantages of using refrigerated containers extend beyond just preserving food quality. The flexibility they offer in logistics is paramount; these containers can be transported via road, rail, and sea, accommodating various supply chain needs. A study published by Logistics Management reveals that temperature-controlled transportation can increase shelf life by up to 50%, allowing for longer distribution routes and the ability to serve a wider market. With the ongoing challenges posed by climate change and fluctuating temperatures, investing in refrigerated containers is not just a business decision but a critical step towards sustainable food transport practices in 2025 and beyond.

Enhanced Food Safety Through Temperature Control

In 2025, the use of refrigerated containers for food transport is anticipated to have a transformative impact on food safety, primarily due to their ability to maintain precise temperature control. According to a report by the Global Food Safety Initiative, maintaining proper temperatures during transportation can reduce foodborne illnesses, which affect approximately 600 million people annually worldwide. By keeping food items at optimal temperatures, refrigerated containers prevent the growth of harmful bacteria and preserve the quality and nutritional value of perishable goods.

Additionally, temperature-controlled logistics are projected to save the food industry around $35 billion annually by minimizing spoilage and waste. The International Journal of Food Science emphasizes that up to 25% of food products can spoil during transportation due to temperature fluctuations. By utilizing advanced refrigeration technologies, businesses can ensure a stable cold chain, safeguarding food from harvest to table. This shift not only enhances food safety but also boosts consumer confidence in food products, critical in an era where transparency and quality assurance are paramount in the food supply chain.

Top Benefits of Using Refrigerated Containers in 2025 for Food Transport

In 2025, the use of refrigerated containers significantly enhances food safety through effective temperature control. The chart below illustrates the percentage of various food types that benefit from temperature-controlled transport, highlighting the importance of this technology in preserving quality and safety.

Cost-Efficiency in Logistics with Refrigerated Solutions

The logistics industry in 2025 is increasingly leaning towards the use of refrigerated containers due to their substantial cost-efficiency in food transport. According to a report by the Global Cold Chain Alliance, the cold chain market is projected to grow at a CAGR of 12.5% between 2021 and 2026, emphasizing a rising demand for temperature-controlled logistics solutions. This growth reflects the food industry's need to minimize spoilage and waste during transit, which significantly impacts overall costs. The ability to transport perishable goods reliably not only preserves quality but also reduces financial losses associated with spoilage, potentially saving businesses up to 30% in logistics costs.

Moreover, the technological advancements in refrigerated containers have made them more energy-efficient, further enhancing their cost-effectiveness. A study from the International Society of Refrigerated Warehouses outlines that modern refrigerated transport systems can operate at a 20% lower energy consumption rate than their predecessors, leading to substantial savings on operational expenses. This efficiency is crucial for businesses seeking to maintain competitive prices without compromising the integrity of their products. By investing in refrigerated solutions, companies are not only ensuring compliance with safety standards but are also optimizing their supply chain operations, positioning themselves for greater profitability in a rapidly evolving market.

Top Benefits of Using Refrigerated Containers in 2025 for Food Transport

| Benefit | Description | Cost Savings (%) | Sustainability Impact |

|---|---|---|---|

| Temperature Control | Maintains optimal temperatures for food safety | 15% | Reduces spoilage waste |

| Flexibility | Adaptable to various transportation needs | 10% | Optimizes resources |

| Reliability | Consistent performance, minimizing disruptions | 20% | Supports local economies |

| Cost Efficiency | Reduces overall logistics and operational costs | 25% | Decreases carbon footprint |

| Safety Compliance | Meets strict food safety regulations | 5% | Ensures food quality standards |

Sustainability and Environmental Impact Considerations

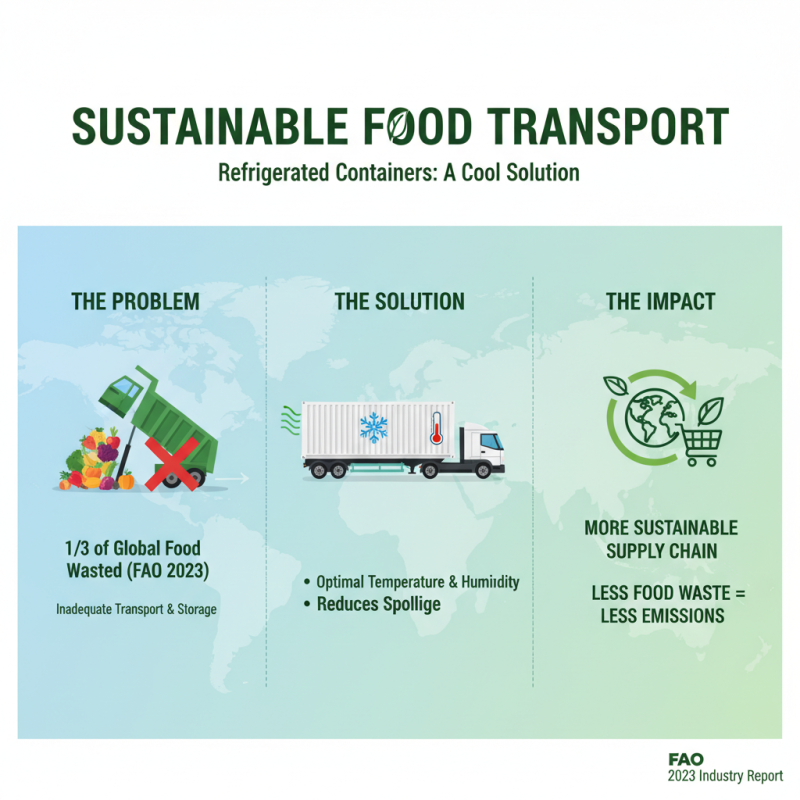

The increasing focus on sustainability has led the food transport industry to seek innovative solutions, and refrigerated containers are at the forefront of these efforts. According to a 2023 industry report by the Food and Agriculture Organization (FAO), approximately one-third of food produced globally is wasted, largely due to inadequate transportation and storage conditions. Refrigerated containers not only address this issue by maintaining optimal temperature and humidity levels, but they also contribute to significant reductions in food spoilage, which is essential for a more sustainable food supply chain.

In addition to minimizing waste, refrigerated containers are increasingly designed with energy-efficient technologies. Research conducted by the International Institute of Refrigeration indicates that modern refrigerated units have achieved energy consumption reductions of up to 30% compared to older models. This not only lowers operational costs but also decreases the carbon footprint associated with food transport. With transportation contributing to nearly 24% of global greenhouse gas emissions, the shift toward more eco-friendly refrigeration solutions is crucial in mitigating environmental impacts and promoting sustainability in food distribution networks.

Technological Innovations in Refrigerated Container Design

In 2025, the food transport industry is set to experience significant advancements due to the emergence of technologically innovative refrigerated container designs. These new systems incorporate enhanced insulation materials and energy-efficient refrigeration units, which help maintain optimal temperatures for perishable goods during transit. According to a recent report by the International Institute of Refrigeration (IIR), innovations in insulation technology can improve energy efficiency by up to 30%, resulting in reduced operational costs and a smaller carbon footprint for logistics companies.

Moreover, the integration of IoT (Internet of Things) technology in refrigerated containers is transforming monitoring and management practices. Real-time temperature and humidity tracking systems are now standard in advanced containers, enabling transporters to optimize conditions and respond promptly to any discrepancies.

A study by the Food Logistics Association highlighted that these innovations can decrease spoilage rates by up to 25%, ensuring that food products arrive in perfect condition while minimizing waste. With these technological advancements, refrigerated container designs are not only becoming more efficient but also more reliable, fundamentally enhancing food transport logistics.

Related Posts

-

Top 10 Benefits of Using Refrigerated Shipping Containers for Your Business

-

Why Choose a Box Container for Your Shipping and Storage Needs?

-

How to Manage Empty Shipping Containers Effectively and Save Costs

-

Top 10 Benefits of Using a 20ft Refrigerated Container for Your Business

-

40 ft Container Tips for Efficient Shipping and Cost Saving Solutions

-

How to Choose the Best 10 Foot Storage Container for Your Needs