40 ft Container Tips for Efficient Shipping and Cost Saving Solutions

When it comes to international shipping, choosing the right container can significantly impact both efficiency and cost. The 40 ft container, a standard in the shipping industry, offers ample space for a wide variety of goods, making it a popular choice among shippers and businesses alike. However, to maximize the benefits of this container size, it is crucial to implement strategic practices that streamline the shipping process and reduce expenses.

Efficient shipping solutions, particularly involving the 40 ft container, require careful planning and execution. From optimizing loading patterns to selecting the best shipping routes, every decision made can contribute to considerable cost savings and enhanced delivery performance. Additionally, understanding the specific requirements and limitations associated with the 40 ft container allows shippers to make informed choices that align with their logistical goals.

By exploring various tips and solutions tailored for the 40 ft container, businesses can better navigate the complexities of shipping, ensuring their goods reach their destinations safely and affordably. In this article, we delve into effective strategies that can lead to improved shipping practices and substantial savings, enabling companies to thrive in the competitive marketplace.

40 ft Container Overview: Capacity and Typical Uses in Shipping

A 40 ft container is a popular choice in shipping due to its substantial capacity and versatility. Typically, a 40 ft container offers around 2,390 cubic feet of storage space, accommodating various types of cargo including household goods, industrial products, and even vehicles. This large capacity allows businesses to maximize their shipping volume, reducing the overall costs per unit transported. Ideal for both international and domestic shipping, these containers are commonly used in the freight industry, making them a staple for logistics companies.

When considering efficient shipping with a 40 ft container, there are several tips to keep in mind. Firstly, ensure optimal loading techniques to utilize the available space fully, which can lead to significant cost savings. Using packing materials and arranging items in a way that minimizes voids will not only protect the cargo but also enhance stability during transit. Secondly, consider consolidating shipments to lower costs and improve efficiency, as shipping full containers instead of LCL (Less than Container Load) can greatly reduce freight expenses. Lastly, always review shipping routes and options, as selecting the right carrier and avoiding peak shipping times can further help in managing costs effectively.

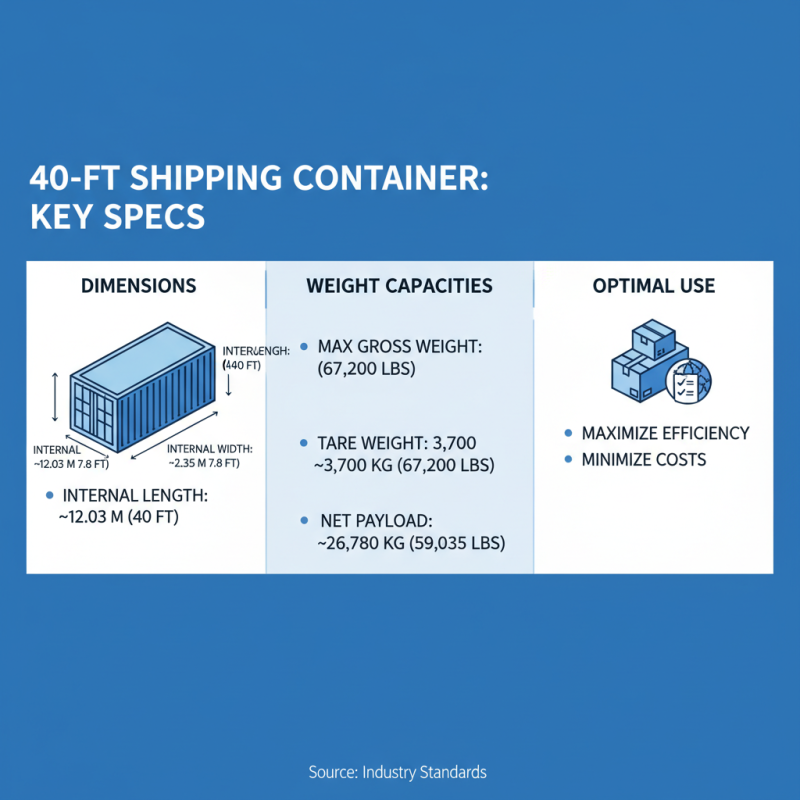

Understanding Container Dimensions: Weight Limitations and Carrying Capacity

When considering shipping with 40 ft containers, understanding their dimensions and weight limitations is crucial for maximizing efficiency and minimizing costs. A standard 40 ft container has an internal length of about 12.03 meters and a width of 2.35 meters, providing ample space for cargo. However, the carrying capacity can be affected by the nature of the goods being shipped. It is imperative to be aware of both the maximum gross weight, typically around 30,480 kg (67,200 lbs), and the net weight capacity, which is influenced by the container's tare weight of approximately 3,700 kg (8,165 lbs).

Moreover, adhering to weight limitations ensures that the shipping process remains compliant with international regulations, reducing risks associated with overloading. It is advisable to utilize a load calculation to balance weight distribution properly within the container, preventing damage during transit. Properly maximizing the carrying capacity by efficiently packing cargo and considering weight distribution not only enhances safety but also saves costs associated with shipping fees and potential penalties. By taking these factors into account, businesses can optimize their shipping operations, making the most out of every 40 ft container shipment.

Key Strategies for Optimizing Container Space Utilization in Shipments

When it comes to shipping, maximizing container space is crucial for both efficiency and cost savings. One key strategy is to employ proper packing techniques. By utilizing modular packaging, companies can significantly reduce empty spaces within the container. Choosing the right box shapes, such as cubes or rectangles, can also facilitate tighter stacking and organization, allowing more goods to fit into the same container volume.

Another effective approach is to analyze weight distribution systematically. Heavy items should be placed at the bottom with lighter items stacked on top to maintain balance and stability during transport. Additionally, leveraging technology, such as load optimization software, can assist in creating a detailed packing plan.

These tools help visualize the container layout, ensuring that all available space is efficiently utilized, leading to reduced shipping costs and enhanced delivery timelines. By focusing on these strategies, businesses can optimize their shipments and achieve greater profitability.

Reducing Shipping Costs: Effective Tips for 40 ft Container Shipping

When it comes to shipping goods in a 40 ft container, effectively reducing shipping costs is paramount for businesses seeking to maximize their profit margins. One of the first tips is to optimize the load. By maximizing the space in the container, businesses can ensure they are getting the most out of their shipping fees. This includes strategically placing items to avoid wasted space and considering the use of pallets for more efficient stacking.

Another effective tip is to compare freight rates from various shipping companies. Different providers may offer varying prices for the same service, and taking the time to shop around can yield significant savings. Additionally, consider consolidating shipments. By combining multiple smaller shipments into one full container load, you not only save on freight costs but also decrease the environmental impact of shipping.

Don’t overlook the importance of proper packaging. Using lightweight and durable materials can help reduce the overall weight of the cargo, potentially lowering shipping fees while protecting your goods during transit. These small adjustments can lead to substantial long-term savings in your shipping operations, making them essential for any business looking to cut costs without sacrificing efficiency.

Shipping Cost Analysis for 40 ft Containers

This chart illustrates the average shipping costs associated with a 40 ft container based on different shipping routes and methods. The data reflects the need for cost-saving solutions in container shipping.

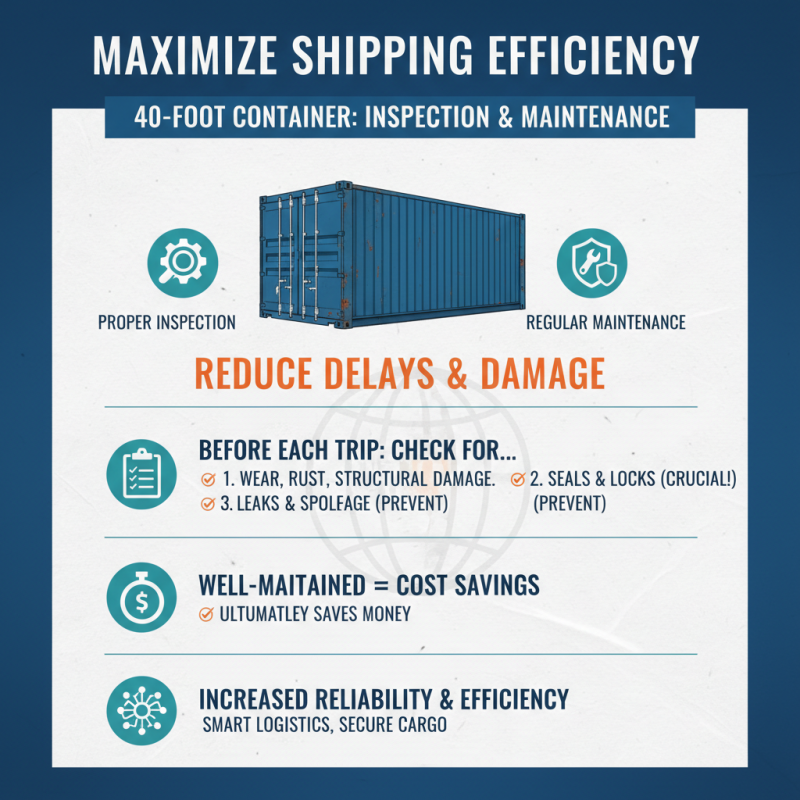

Best Practices for Container Inspection and Maintenance to Ensure Efficiency

When it comes to maximizing efficiency in shipping, proper inspection and maintenance of 40 ft containers cannot be overlooked. A well-maintained container reduces the risk of delays and damage, ultimately saving costs. It's essential to conduct regular inspections before each trip. Check for any signs of wear, rust, or structural damage. Paying attention to the seals and locks is crucial, as compromised seals can lead to leaks and spoilage of goods.

Another best practice is to keep your containers clean and dry. Moisture can lead to mold growth, especially when transporting perishable goods. After each use, ensure to conduct a thorough cleaning, removing any debris or residues. Regularly updating your maintenance log will also help to keep track of repair needs and replacement schedules, ensuring that all containers remain in top condition.

Lastly, consider investing in preventive maintenance. Instead of waiting for issues to arise, proactively address wear and tear. This could involve applying protective coatings or replacing worn parts before they lead to bigger problems. By following these maintenance tips, you can enhance the efficiency of your shipping processes while saving on potential costs caused by container-related issues.