20 Tips for Choosing the Right 20ft Refrigerated Container?

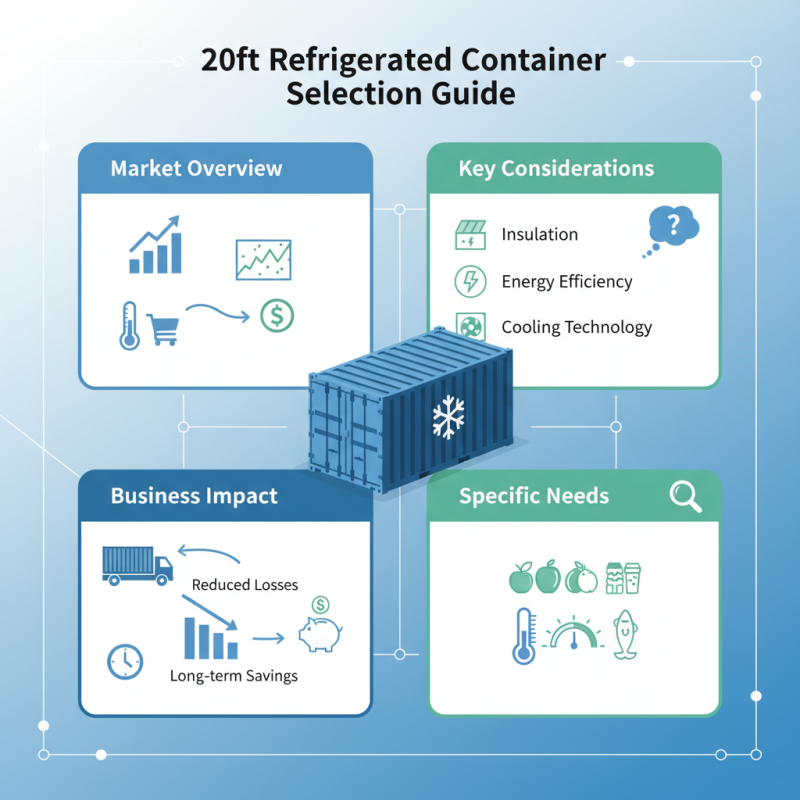

Choosing the right 20ft refrigerated container can significantly impact your business operations. The global cold chain market was valued at over $200 billion in 2021, with a projected CAGR of 14% through 2027. This underscores the importance of selecting the right equipment. A 20ft refrigerated container is ideal for transporting perishable goods. It maintains the necessary temperature and ensures product integrity.

However, purchasing a refrigerated container is not straightforward. You must consider various factors, including insulation, energy efficiency, and cooling technology. For example, a container with a powerful refrigeration unit can save you on energy bills. Nevertheless, not all containers are created equal. Some may lack optimal insulation, which can increase energy consumption.

When choosing a 20ft refrigerated container, think about your specific needs. The type of goods you transport can dictate the ideal temperature controls. Many buyers overlook these details, leading to potential losses. Taking the time to assess your requirements can lead to better decision-making and long-term savings.

Understanding Your Refrigeration Needs for a 20ft Container

Understanding your refrigeration needs for a 20ft container is crucial. An estimated 90% of global trade relies on efficient temperature control. This container size is popular for shipping perishable goods. It can typically hold about 11 standard pallets. Knowing the right refrigeration system is key to preserving the quality of your cargo.

Temperature range is essential. For perishable items, the ideal range is often between 0°C and 4°C. Some goods like flowers or certain seafood might need even tighter controls. The cargo's nature dictates temperature management. This needs careful consideration when choosing your unit. Industry reports show that improper temperature can lead to spoilage rates of up to 30%.

Energy consumption matters too. Containers can consume between 1.5 and 3.5 kWh per day. This variation may seem minor, but it adds up quickly. Assessing your energy needs upfront will help you avoid surprises. Placement of the container also influences performance. Ensure it’s not exposed to direct sunlight or extremes of temperature.

Many factors can complicate the choice. Shipping conditions, distance, and duration matter. Have a clear plan for your cargo's journey. Regular checks could save you time and money later. Research and data can help guide your decisions. Keep in mind the balance between quality, cost, and efficiency.

Evaluating the Ideal Temperature Range for Specific Cargo Types

Choosing the right temperature range is crucial for transporting perishable goods. Different cargo types require specific temperatures to maintain their quality. For instance, fresh fruits and vegetables generally thrive at temperatures between 34°F and 40°F. This helps preserve their texture and prevent spoilage.

Meat products, on the other hand, need stricter controls. They usually require lower temperatures, ideally around 28°F to 32°F. This ensures that bacteria do not proliferate. However, managing humidity levels is also essential. Too much moisture can lead to unwanted spoilage, while too little may cause dehydration.

It’s easy to overlook these details. Many choose a container based on price rather than temperature regulations. However, this approach can lead to significant losses. You may think that all cargo is created equal, but it’s not. Understanding each type’s needs is vital for success in shipping.

Assessing Energy Efficiency and Power Options for Chill Storage

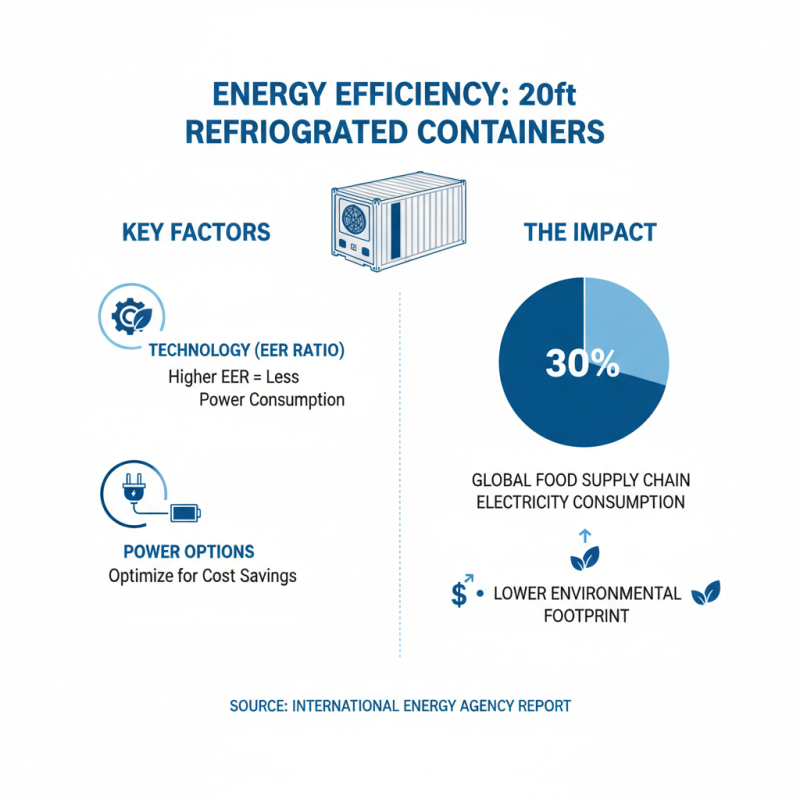

When evaluating energy efficiency for a 20ft refrigerated container, consider both the technology and the refrigeration unit's power options. According to a report from the International Energy Agency, refrigeration can account for up to 30% of electricity consumption in the food supply chain. Choosing a model with a high energy efficiency ratio (EER) helps address this challenge. Units with a higher EER consume less power, reducing operational costs in the long run.

Explore renewable energy options, such as solar panels, to power the container. The Solar Energy Industries Association highlights that solar installations can significantly decrease reliance on non-renewable energy sources. Many refrigerated containers can accommodate solar setups, which offer cost savings. However, proper exposure to sunlight is crucial. Depending on the location, this may not be feasible year-round.

Also, consider the insulation materials used in the container. Effective insulation reduces the workload on the cooling system. An insulated unit can maintain temperature longer, even with power fluctuations. Reduced cooling demand translates to less energy usage. It's vital to balance budget constraints with quality needs. Not all models achieve the same level of insulation. Thorough research on insulation performance is essential before deciding.

Considering Transportation and Accessibility Issues for Container Placement

When considering the placement of a 20ft refrigerated container, transportation and accessibility are crucial elements. Ensure the site is easily reachable for delivery trucks. A narrow road may complicate access and create delays. If the location has low-hanging branches, containers could get damaged during delivery. Measure the entry points to avoid surprises.

Placement also involves proximity to power sources. Is a power outlet within reach? If not, an extension cord may be necessary, or you might need a generator. Poor accessibility can lead to extra costs and time lost. Think about the distance from your storage area. It should be close enough for easy loading and unloading.

Environmental factors matter too. Is the area prone to flooding? Is it in direct sunlight? Such conditions could impact the container’s effectiveness. Assess the surrounding landscape for any potential hazards. If placement is not optimal, it could lead to operational issues. Planning for these aspects in advance can save future headaches.

Exploring Maintenance and Service Options for Long-term Use

When investing in a 20ft refrigerated container, maintenance is crucial for longevity. Regular checks can prevent costly repairs. It's vital to inspect seals, doors, and insulation frequently. Look for signs of wear and tear. Simple problems can escalate into major issues. This attention to detail ensures the container remains efficient and reliable.

Service options should not be overlooked. Find a reliable technician for routine maintenance. They can provide valuable insights into the container's performance. Regular servicing can spot issues early. Some owners may neglect this, leading to larger expenses later. A well-maintained unit runs better and saves energy costs.

Monitoring temperature settings is key for product integrity. Anomalies can occur without warning. It's helpful to keep a log of temperatures daily. Be proactive in addressing any irregularities. Small adjustments can make a significant difference. Each step contributes to a more efficient operation, ensuring that your refrigerated container remains a valuable asset.

Related Posts

-

Top 10 Benefits of Using a 20ft Refrigerated Container for Your Business

-

Top 10 Cold Storage Containers for Efficient Temperature Control Solutions

-

Top 10 Benefits of Using Refrigerated Shipping Containers for Your Business

-

How to Manage Empty Shipping Containers Effectively and Save Costs

-

How to Choose the Right Large Shipping Container for Your Needs?

-

How to Use an 8ft Shipping Container for Storage and Transport?